Artículo #208

In search of the fermentative distinction

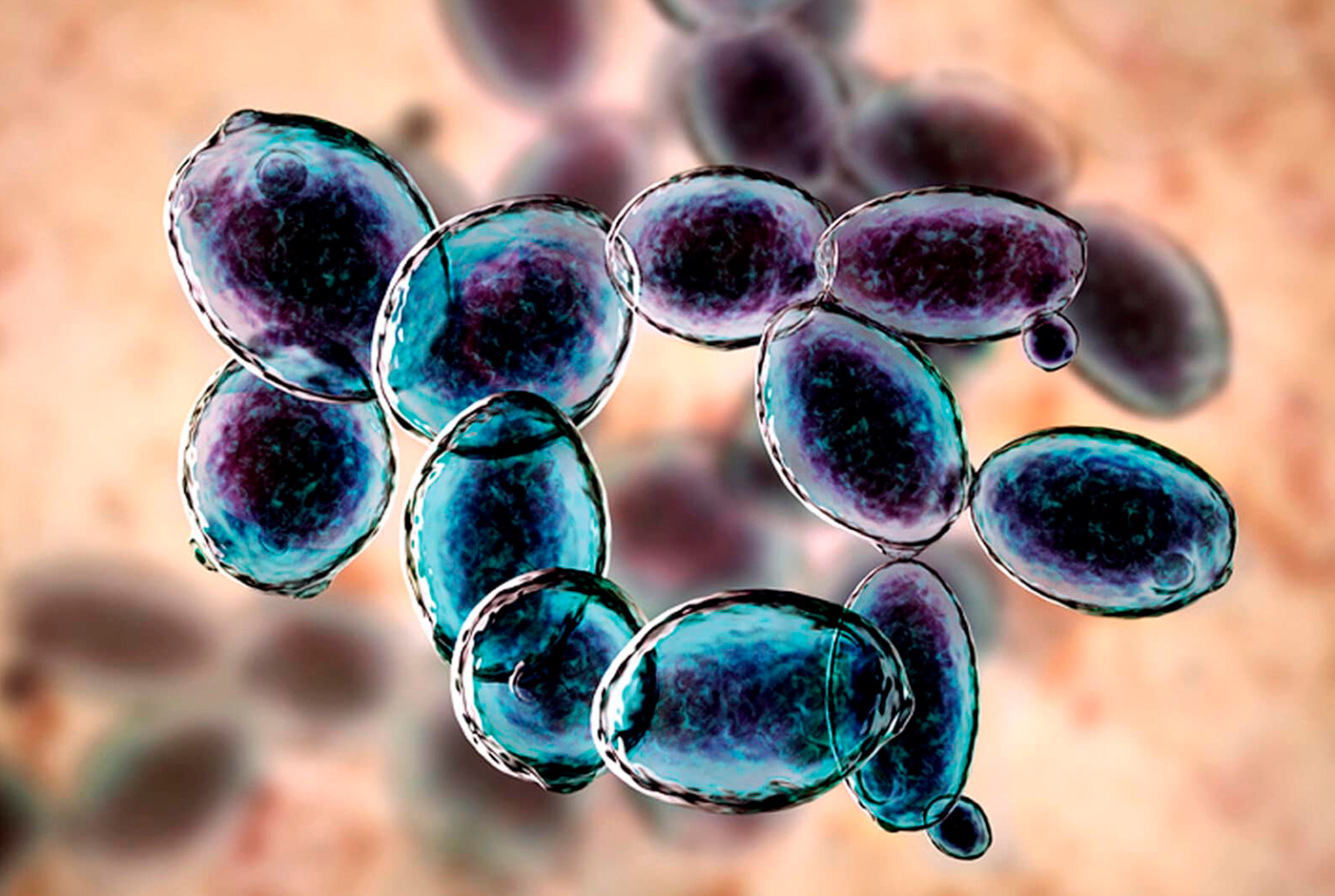

In the pursuit of winemaking excellence, fermentation stands out as a pivotal process, with yeasts playing a central role. This transformation of grape must into a complex, aromatic beverage is closely tied to the metabolic activity of microorganisms, particularly the species Saccharomyces cerevisiae. However, recent scientific advancements have highlighted the significant contribution of non-Saccharomyces yeasts to the sensory quality of wine, challenging the long-held belief that these microorganisms were undesirable in the fermentation process. This shift in understanding has sparked renewed interest in oenological research, encouraging the exploration of microbial diversity and its impact on wine's chemical composition and aromatic profile. Within this context, the present work seeks to examine the multifaceted nature of wine fermentation, emphasizing the role of non-Saccharomyces yeasts and their potential to enhance the sensory complexity of the final product.

Texto destacado

Non-Saccharomyces yeasts emerge as key elements in winemaking, offering new possibilities to enrich the aromatic and sensory profile.

Wine can be understood as a complex matrix composed of compounds with varying chemical properties, where volatile compounds play a primary role in defining its aromatic quality. The aroma and flavor of wine result from numerous volatile compounds produced during alcoholic fermentation (AF), including alcohols, esters, organic acids, phenols, thiols, monoterpenes, and norisoprenoids. These compounds are primarily formed through the metabolic processes of yeast during AF. Extensive microbiological research has established that S. cerevisiae is chiefly responsible for AF, significantly influencing the sensory characteristics of wine and modulating the activity of other yeast genera and species, known as non-Saccharomyces yeasts, which contribute positively to the sensory profile.

Recent studies have demonstrated that non-Saccharomyces yeasts, once considered undesirable or spoilage organisms, can enhance the chemical composition and aromatic complexity of wine. Their metabolic activity is now recognized as fundamental to shaping the final aromatic profile. Consequently, the metabolism of these microorganisms may be a crucial factor in determining the aroma and overall quality of wine. Despite this, research explaining the precise impact of non-Saccharomyces yeasts on the aroma profile remains limited. This review aims to summarize key aspects of aroma compound synthesis by non-Saccharomyces yeasts. Studies of yeast activity during the fermentation process have identified several prominent genera, including Saccharomyces, Metschnikowia, Debaryomyces, Hanseniaspora, Kloeckera, Pichia, and Torulaspora (Fleet et al., 1984). Nevertheless, S. cerevisiae remains the species primarily responsible for alcoholic fermentation.

Currently, winemakers commonly use S. cerevisiae starter cultures to standardize the fermentative microbiota and prevent undesirable yeast species from dominating the fermentation process. These cultures rapidly outcompete other yeasts, ensuring the quality of the final product by minimizing the influence of other microorganisms present during fermentation. However, this homogenization may negatively impact the typicity of the wines, particularly in relation to their sensory attributes. This has sparked ongoing debate regarding the use of S. cerevisiae inoculums, as they provide consistency but may do so at the cost of reducing the aromatic complexity of the final product.

The study of yeasts

Numerous studies have examined the correlation between different S. cerevisiae strains and the resulting wine aroma (Coghe et al., 2004). These reports indicate that not only S. cerevisiae influences the sensory quality of wine, but also the metabolic activity of other yeast genera and species, referred to as non-Saccharomyces yeasts, which positively impact sensory characteristics. However, despite their aromatic potential, many of these yeasts exhibit low fermentative capacity due to their limited alcohol tolerance, preventing them from completing fermentation. This limitation has restricted their use in the wine industry, despite their significant potential.

One strategy currently employed in the industry is the use of mixed cultures, combining non-Saccharomyces species with S. cerevisiae strains. This approach leverages the sensory benefits of non-Saccharomyces yeasts while capitalizing on the strong fermentative ability of S. cerevisiae, enhancing sensory complexity and, therefore, improving the overall quality of the wine (Maurizio Ciani et al., 2010).

Among non-Saccharomyces yeasts, Torulaspora delbrueckii has garnered significant interest due to its ability to positively alter the aromatic profile of wine. It is known to produce higher levels of fruity esters, thiols, and terpenes, while generating lower concentrations of higher alcohols, thereby preserving the grape's original character (Azzolini et al., 2015; Belda et al., 2017; Renault et al., 2016). Additionally, T. delbrueckii tends to produce low levels of acetic acid (Bely et al., 2008), a key quality parameter in winemaking.

Furthermore, T. delbrueckii has been reported to produce wines with higher glycerol levels (Belda et al., 2015) and, consequently, lower ethanol concentrations (Contreras et al., 2014). This characteristic is especially relevant in the context of climate change, as rising sugar levels in grape musts have resulted in wines with higher alcohol content. During alcoholic fermentation, ethanol production is usually higher than 12% (v/v), so the associated microorganisms must have mechanisms of resistance to this compound. In practice, the phenotype of ethanol resistance among oenological yeasts is heterogeneous, with S. cerevisiae having the highest level of resistance and leading alcoholic fermentation. However, yeast species other than Saccharomyces play an important role during the early stages of spontaneous alcoholic fermentation, when the ethanol concentration is not very high (Taillandier et al., 2014). Because of the latter, the strategy of mixed and/or sequential fermentations is currently used, combining non-Saccharomyces yeasts with a yeast with a higher fermentative profile such as S. cerevisiae, which in most cases is necessary to adequately complete the industrial alcoholic fermentation process.

It has been described that T. delbrueckii is able to ferment and tolerate up to an ethanol concentration slightly higher than 9% (v/v) (M. Ciani & Maccarelli, 1997). On the other hand, Bely et al. (2008) have reported that this value is lower, reaching only 7.4% (v/v). However, Belda et al. (2015, 2017), through population kinetics studies in sequential fermentation, observed that T. delbrueckii suffered a significant decrease in cell viability when ethanol levels exceeded 8% (v/v). This suggests that the ethanol resistance of T. delbrueckii is limited and much lower than that of S. cerevisiae, complicating its use in industrial fermentations. However, to improve the fermentation rate of selected non-Saccharomyces yeasts, sequential cultures are used, but this is to the detriment of the diversity of aromas that could be present in the final product. Given this context, ethanol resistance is an important factor in the selection of non-Saccharomyces industrial strains and particularly T. delbrueckii (Catrileo et al., 2020).

On the other hand, Kluyveromyces species are not usually involved in spontaneous fermentation processes because they have a low fermentation capacity and slow multiplication (Fonseca et al., 2008). However, they are capable of producing considerable amounts of lactic acid (1.5 to 1.8 g/l) and low amounts of acetic acid. Kluyveromyces species have been reported to produce aromatic compounds such as esters, monoterpene alcohols, carboxylic acids, ketones, furans and isoamyl acetate in liquid phase fermentation. Of all these compounds, the production of 2-phenylethanol (2-PE) stands out (Wittmann et al., 2002), with rose petal aroma, which has commercial importance, as it confers characteristics that positively influence wine quality, among others (van Breda et al., 2013). In particular, the influence of carbon source (Fabre et al., 1998; Medeiros et al., 2001), aeration rate (Medeiros et al., 2001), composition (Etschmann et al., 2004) and growth conditions (Etschmann & Schrader, 2006) on aroma production in K. marxianus has been studied.

Species from other yeast genera, such as Hanseniaspora, which are ubiquitous in wine environments, have been proposed as yeast starters in winemaking (Cian et al., 2016). For instance, mixed culture fermentations involving H. guilliermondii and S. cerevisiae has demonstrated higher concentrations of acetate esters compared to fermentations using only S. cerevisiae. This enhancement in acetate ester levels occurs without significantly impacting acetaldehyde, acetic acid, glycerol, or higher alcohols (Rojas et al., 2003). However, H. vineae has been reported to contribute aromatic complexity to wines by producing key aromatic compounds (Lleixà et al., 2016). Despite this, sensory evaluations of wines made with this apiculate yeast are still limited and results remain inconsistent. Medina et al. (2013) observed that fermentation with H. vineae resulted in up to tenfold higher levels of 2-phenylethyl acetate compared to conventional and spontaneous fermentations. Conversely, the concentration of 2-phenylethyl alcohol was notably lower.

Metschnikowia pulcherrima is among the non-Saccharomyces yeast species with the highest capacity for synthesizing extracellular hydrolytic enzymes. This species produces a range of enzymes, including pectinase, protease, glucanase, lichenase, β-glucosidase, cellulase, xylanase, amylase, sulfite reductase, lipase, and β-lyase (Barbosa et al., 2018; Ganga & Martínez, 2004; Jolly et al., 2006; Reid et al., 2012). Its high proteolytic activity makes it a promising candidate for use in fermentations with S. cerevisiae, as it releases amino acids and increases the availability of nitrogen sources for S. cerevisiae growth (Morata et al., 2019; Romano et al., 2006). Additionally, M. pulcherrima is noted for its glucosidase activity (Fernandez et al., 2000; Zott et al., 2011), which is enhanced under aerobic conditions (Ferreira et al., 2001), promoting the release of varietal aromas by hydrolyzing bound monoterpenes.

Terpenes and malolactic fermentation

Terpenes play a crucial role in defining the varietal character of several white grape varieties, serving as primary descriptors for varieties such as Moscatel, Riesling, and Albariño (Marais, 2017). However, the composition of free terpenes in grape must is relatively low, with a significant presence of glycosylated terpenes (Maicas & Mateo, 2005). These glycosylated terpenes can be released through enzymatic hydrolysis by glycosidase enzymes (Gunata et al., 1994; Mateo & Stefano, 1997). Notable terpenes in this group include linalool, geraniol, nerol, citronellol, and alpha-terpineol (Gunata et al., 1994; Marais, 2017).

Mixed fermentations involving M. pulcherrima and S. cerevisiae have been shown to produce higher levels of acetate esters and β-damascenone, while reducing the levels of C6 alcohols in Icewine made from Vidal Blanc grapes (Zhang et al., 2018). Similarly, these mixed fermentations have been associated with increased production of higher alcohols, including isobutanol and phenylethanol (Prior et al., 2019).

L-malic acid, found in grape must, varies in concentration depending on grape variety and climatic conditions. During malolactic fermentation (MLF), lactic acid bacteria convert L-malic acid into lactic acid, leading to a reduction in total acidity and an increase in the pH of the must (Lonvaud-Funel, 2015). However, factors such as ethanol concentration, pH, temperature, and sulfur dioxide (SO2) levels can influence the successful completion of MLF (Wibowo et al., 1988).

An alternative to MLF is maloethanolic deacidification performed by Schizosaccharomyces pombe (Benito et al., 2012; M. Ciani, 1995). This yeast exhibits high tolerance to low pH and high SO2 levels, making it suitable for use in winemaking (Benito et al., 2016). According to Benito et al. (2013), the conversion of malic acid to ethanol by S. pombe can decrease total acidity by approximately 4 g/L and increase final pH by about 0.4.

In conclusion, the detailed study of non-Saccharomyces yeasts highlights their potential to transform wine fermentation, offering aromatic and sensory benefits that enhance the consumer experience. Although traditionally viewed as secondary or undesirable, their positive impact on the quality of the final product is increasingly recognized in the wine industry. Combining these yeasts with S. cerevisiae strains presents a promising opportunity to achieve new standards of fermentation excellence, producing wines with unique and differentiated profiles that reflect the diversity and complexity of the oenological microbial world.

---

About the Author:

Liliana Godoy Olivares

Liliana Godoy Olivares is an Associate Academic at the Pontificia Universidad Católica de Chile, with extensive experience in academia and research. She has served as an Assistant Professor at the Pontificia Universidad Católica de Chile, a Professor of Food Microbiology at Universidad de Santiago, and as Head of the PhD Program in Plant Biotechnology at UC. Her significant research contributions have been made at both the University of Santiago and Lund University in Sweden. With a PhD in Food Science and Technology, she has made substantial advancements in the fields of food microbiology and wine yeasts

(**) Original text corresponding to:

Formation of Aromatic and Flavor Compounds in Wine: A Perspective of Positive and Negative Contributions of Non-Saccharomyces Yeasts.

Liliana Godoy, Andrea Acuña-Fontecilla and Daniela Catrileo.

DOI: 10.5772/intechopen.92562

At: https://www.intechopen.com/chapters/72364

Supporting images courtesy of Agronomist-Enologist Karla Riquelme Rodríguez.